It’s frightening to lose power on the brakes. Drivers can experience a loss of braking efficiency in various ways - overheating, brake fade and degradation. What we call ‘vapour lock’ or ‘spongy pedal feel’ are serious car brake efficiency issues that need in-depth investigation. Let’s take a look at each in turn, with advice from our Champion experts.

A) "Vapour lock" brake efficency problems

A dangerous occurrence, vapour lock is caused by evaporating brake fluid. When you brake, considerable heat is generated and so brake fluid is designed with a high boiling point. But brake fluid is also hygroscopic, which means it absorbs water. In any hydraulic brake system, brake fluid will slowly absorb moisture and its boiling point will drop.

When this water absorption reaches a certain level – after prolonged hard braking (particularly with heavy loads or in hot weather) – the brake fluid can start to boil and create gas bubbles. Gas is far more compressible than liquid, so the driver will experience no pressure at all on the brake pedal and a total loss of power known as vapour lock.

How to maintain car brake efficiency and avoid vapour lock

Start with the right brake fluid

Brake fluid is the life-blood of the braking system. So, choosing a high-performance brake fluid is critical. Vehicle manufacturers often recommend a specific type.

A good brake fluid should:

- be incompressible to give a solid pedal during braking

- have a high boiling point

- maintain performance during absorption of moisture

- have a viscosity that remains within closely defined parameters

- have the correct level of lubricity

- prevent corrosion

- have a controlled rubber swell to prevent shrinkage.

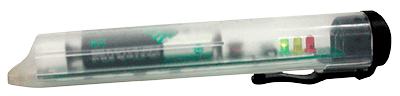

Test the brake fluid

It is fundamental to regularly verify brake fluid conditions. The only real way to know the condition of the fluid is to test it. This is sometimes done with a pen-style tester, which estimates moisture content electronically in a few seconds. This way of testing is not recommended, as there are other brake fluid testers give more accurate readings through industry standard techniques.

It is fundamental to regularly verify brake fluid conditions. The only real way to know the condition of the fluid is to test it. This is sometimes done with a pen-style tester, which estimates moisture content electronically in a few seconds. This way of testing is not recommended, as there are other brake fluid testers give more accurate readings through industry standard techniques.

Change the brake fluid

It’s time to change the brake fluid when the boiling point gets too low. Here are some tips on how to bleed the system and change the brake fluid.

Important pressure check:

Before bleeding the system, carry out a master cylinder leak pass test by attaching a pressure gauge to the closest caliper brake pipe. The system must be pressurised to 50 bar for 45 seconds, during which time there should be no more than a 4 bar loss of pressure. A bigger drop would indicate a master cylinder leak pass, which needs attention. You can also carry out a second check at a lower pressure of 10 bar.

How to bleed brake fluid in cars with front and rear disc brakes

Always bleed brakes in a set order, starting with the brake caliper furthest from the master cylinder (either left-rear or right-rear depending on if it’s left- or right-hand drive).

- With all bleed nipples closed, fit a bleed pipe to the first caliper and loosen the nipple.

- Using slow, full and firm strokes of the brake pedal, continue until the brake fluid is visually (in the bleed pipe) clean, and clear of air bubbles.

- With the pedal fully depressed, tighten the bleed nipple and remove the bleed pipe.

- Continue to the opposite rear caliper and repeat the procedure.

- After completing the rear calipers, make certain the front calipers are also properly functioning and free of air bubbles. Do this by bleeding the front calipers, starting also furthest from the master cylinder and finishing with the closest.

- Lastly, make sure that an adequate pedal pressure is achieved.

How to bleed brake fluid in cars with drum brakes

Always bleed brakes in a set order, starting with the brake caliper furthest from the master cylinder (either left-rear or right-rear depending on if it’s left- or right-hand drive).

Before starting, it’s essential to ensure the correct manual adjustment (if present) is carried out on the brake shoes-to-brake drum clearance, according to the manufacturer’s specifications.

- With all bleed nipples closed, fit a bleed pipe to the bleed nipple, of the wheel cylinder furthest from the master cylinder and loosen the nipple.

- Using slow, full and firm strokes of the brake pedal, continue until the brake fluid is visually (in the bleed pipe) clean, and clear of air bubbles.

- With the pedal fully depressed, tighten the bleed nipple and remove the bleed pipe.

- Continue to the opposite rear wheel cylinder and repeat the procedure.

- After completing the rear wheel cylinders, make sure the front calipers are also properly functioning and free of air bubbles by bleeding the front calipers (starting with the furthest and finishing with the closest to the master cylinder).

- Finally, ensure that an adequate pedal pressure is achieved.

B) ‘Spongy pedal feel’ car brake efficiency problems

What causes spongy pedal?

This car brake efficiency issue is caused by brake fluid leaks. Faulty brake hoses can cause leaks, or ballooning of the hose itself, which leads to a poor brake response.

How to avoid faulty brake hoses:

- Check for ageing – look regularly to see if there is any chaffing, cuts, deterioration or leakage.

- Correct fitment – make sure it’s not twisted or bent, that the correct tightening torque is applied and there is no contact with other suspension parts (once the vehicle has been lowered).

- Quality parts – choose brake hoses that have high resistance, good flexibility, low moisture permeability and low volume expansion under pressure.

The content contained in this article is for entertainment and informational purposes only and should not be used in lieu of seeking professional advice from a certified technician or mechanic. We encourage you to consult with a certified technician or mechanic if you have specific questions or concerns relating to any of the topics covered herein. Under no circumstances will we be liable for any loss or damage caused by your reliance on any content.